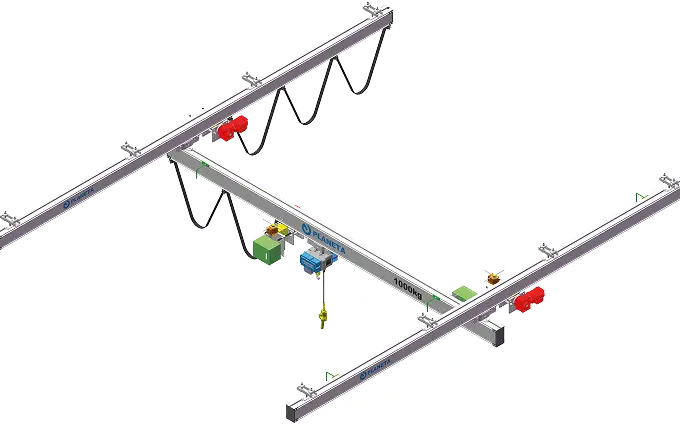

PLANETA LiFT LiNE Aluminium Light Crane System

Maximum Performance. Minimal Footprint. Unmatched Efficiency.

More efficiency and ergonomics with 30% less weight: The PLANETA LiFT LiNE light crane system is optimised for quick installation and continuous industrial operation.

When movement is exhausting and maintenance time-consuming, efficiency drops – and your employees feel the strain.

Increase capacity, optimise processes, reduce strain on staff, and enhance operational safety – with the PLANETA LiFT LiNE light crane system, you gain performance, flexibility, and valuable time in your daily operations.

Catalogue and Technical Details

Download our latest PDF catalogue to discover technical specifications, equipment options, and further information about our light crane systems.

Certified Quality

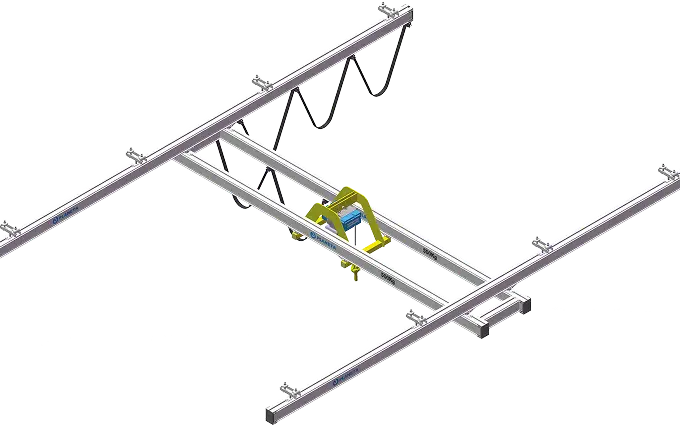

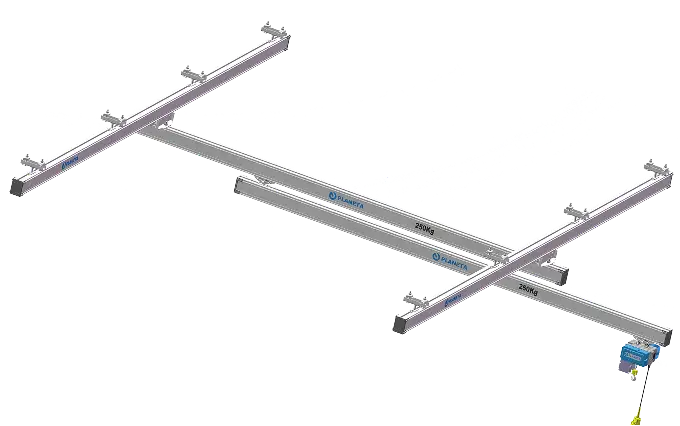

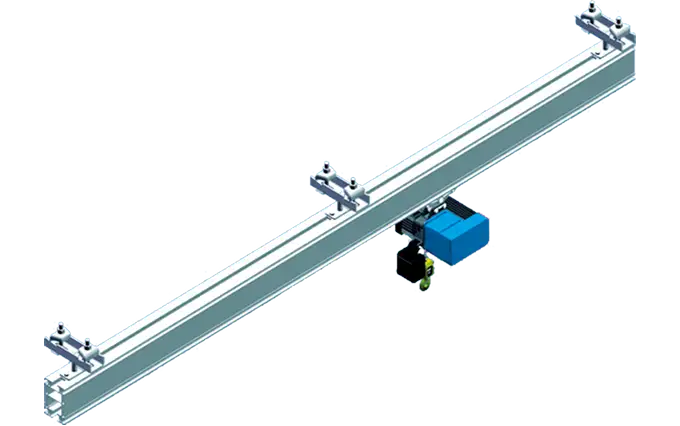

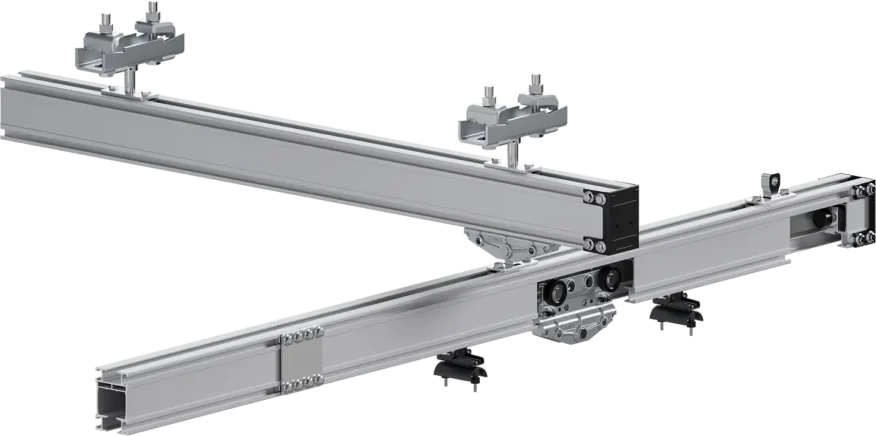

An Overview of the LiftLine System

Contact

Thomas Steffen

Whether you have initial questions, specific requirements or concrete project ideas – we’re here for you. Your dedicated contact at PLANETA LiFT LiNE light crane systems will support you from the initial consultation all the way to the finished solution. Benefit from expert knowledge, short response times, and advice delivered at eye level – as partners.

FAQ

Is technical support available?

Yes – from the initial consultation through installation to ongoing maintenance, our experienced team is at your side. This includes training and service provided by qualified PLANETA specialists.

What about occupational safety?

All components are tested in accordance with European standards and designed with a safety factor of 6. Additional safety features such as end stops and collision protection are also available.

Are individual customisations possible?

Yes – the modular system can be precisely adapted to your spatial and operational requirements, including curved tracks, special beams and additional components.

What are the advantages of aluminium profiles compared to steel?

Aluminium is significantly lighter, corrosion-resistant, and reduces structural load – making it ideal for retrofitting or for support structures with limited load capacity.

Is integration into existing lifting equipment possible?

Yes – the PLANETA LiFT LiNE light crane system is compatible with standard lifting devices such as electric chain hoists or pneumatic hoists and can be easily integrated into existing infrastructure.

How quickly can delivery and installation be carried out?

Thanks to high availability and plug-and-play components, delivery can be arranged at short notice. Installation usually takes just a few hours.

What is the load capacity of the system?

The PLANETA LiFT LiNE light crane system supports loads of up to 2,000 kg – ergonomically optimised and tested according to European safety standards (safety factor 6).

How complex is retrofitting into existing production facilities?

The PLANETA LiFT LiNE light crane system features a modular design and can be installed without tools – usually without interrupting production.

Experience how simple retrofitting can be – with PLANETA.

With the modular PLANETA LiFT LiNE light crane system, you can seamlessly integrate modern lifting solutions into your existing production structures – without conversions or extended downtimes. Benefit from quick installation, high availability, and expert advice that truly understands the needs of your operation.

About PLANETA

Traditionally innovative – since 1861

Company History

Defying Gravity

PLANETA represents the fusion of tradition and forward-thinking innovation in the field of lifting technology. Our origins date back to 1861, when master locksmith Hermann Wilhelmi founded his own workshop in Mülheim an der Ruhr – the beginning of what would later become Wilhelmi Hebezeuge, and since 2003, PLANETA-Hebetechnik. Driven by a constant pursuit of precision, our products soon began to shape not only workshops, but entire industries. Branches in Paris, Vienna and Shanghai followed, becoming key hubs of our broad international presence and expertise. Quality and safety have always been the driving forces behind our growth – and our certifications according to DIN EN ISO 9000:2001 and the strict regulations for Occupational Health and Safety (OHS) are not just framed on the wall, but lived promises reflected in every product and service we deliver. Today, PLANETA is not only contributing to the future of lifting technology – we are helping to redefine it. Our mission is to perfect our equipment so that it doesn’t just lift loads – it elevates safety, efficiency, and technical progress for our customers.

Certified quality

Standardised processes and the highest quality standards are the cornerstones of our commitment and identity – and have been for over 150 years.

Certifications

Memberships

Challenge: Gravity. Our products provide efficient solutions that lift and move.

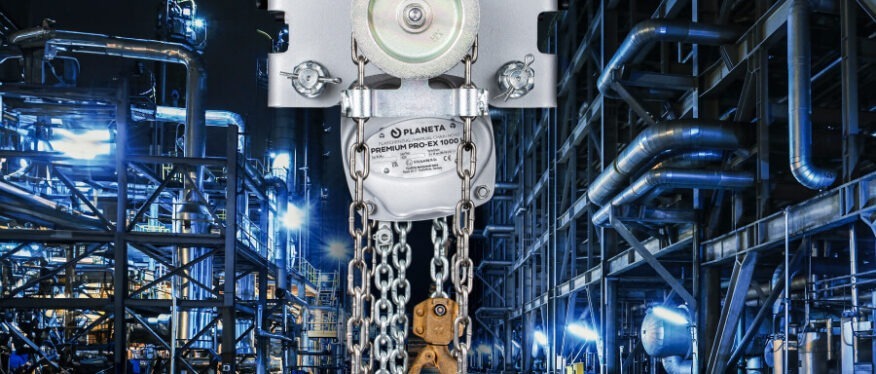

Lifting technology

Discover our wide range of hoist products that enable you to work safely and efficiently. Whether manually operated hoists or electric chain hoists – our expertise secures your project with robust and reliable technology.

Winches

Maximise your productivity with our winches. Engineered for precision and power, they are the ideal choice for demanding applications. Every unit is built with an uncompromising focus on quality.